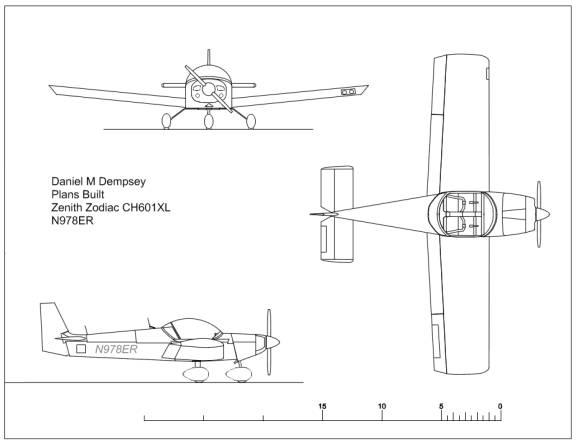

Builder: Daniel Dempsey

Number N978ER

Serial Number 1

December 02, 2013

This is the

original draft of this manual produced

before the airplane has been flown.

Table of Contents

Zodiac CH 601 XLB – Aircraft Data

Airspeed Calibration Table in Knots

(Flaps Up)

Airspeed Calibration Table in Knots

(Flaps Down)

Engine Failure In Flight (Restart Procedure)

Power Off Landing (assumes off runway)

Precautionary Off Runway Landing

Electrical Power System Malfunctions

Volt Meter shows excessive voltage

Amplified Emergency Procedures

Engine Failure In Flight (Restart

Procedure)

Inside Airplane Pre-Flight Inspection

Zodiac CH 601 XLB – Aircraft Data

Aircraft Type: Plans Built Zodiac CH 601 XLB

Category: Single Engine Land

Designer: Chris Heinz of Zenith Aircraft Company

Builder: Daniel Dempsey

1051 Hopkins Court

Charlottesville VA, 22901

Years of Construction: 2005->2013

Registration Number: N978ER

Aircraft Serial Number: 1

Plans Serial Number: 54

Plans Date 2003

Power Plant Corvair Conversion

Engine Serial Number T091RH

Propeller Hand Carved by Builder

Date of Manufacture 08/08/2013

Introduction

This manual describes the proper operation of the plans built Zodiac 601 XLB constructed by Daniel Dempsey between Spring 2005 and August 2013.

This aircraft is intended to be flown by competent experienced pilots after familiarization with the contents of these instructions. The pilot of this aircraft should be thoroughly familiar with the operating limitations, normal and emergency procedures from this manual.

For maintenance instructions see the Maintenance Manual.

For operating or service updates see the Zenith website at: http://www.zenithair.com/zodiac/xl/index.html

WARNING: Operating this aircraft outside of its operational limitations can lead to death of the pilot, passengers and those on the ground. So DON”T DO IT.

Background Information

Airframe

The

airplane is a Zenith Zodiac CH601XLB designed by Chris Heinz and built from

plans. The Zodiac is a two place low

wing all metal aircraft. The CH601XL

has a few unusual design features, such as the all-flying rudder and the

flexible aileron hinges, but is otherwise a very conventional light aircraft. I built the aircraft in our family living

room while living in Nelson County Virginia.

The plans were purchased in 2004 and construction was begun in

2005. Construction was completed in the

Fall of 2013. The aircraft has the

structural upgrade kit applied that came out in December of 2009. I made all the fiberglass parts other than

the spinner. The nose bowl and cowling

are of my own design. The aircraft is

equipped with the long range fuel capacity option.

Engine

The

airplane is powered by a Corvair auto conversion that was also built by

me. The engine core was from a 1967

Chevrolet Corvair automobile. This car

sported a 6 cylinder air cooled boxer that put out 110 horse power. The Corvair auto conversion was done using

a conversion manual authored by William Wynne.

The conversion provides 100 HP using a direct drive (no reduction gear)

to the propeller. I made the parts to

do the conversion in my father’s machine shop in Rustburg Virginia. The engine uses a fifth bearing upgrade to

the engine purchased from Dan Wessman.

I replaced his adjustable centering crankshaft extension with a single

piece extension of my own design. I made the engine mount by making slight

modifications to the mounts shown for other engines in the Zenith plans. The carburetor is from a 1957 MGA

automobile.

Propeller

I also

made the propeller for this airplane.

The propeller is 58” in diameter and has a 56” pitch at the tips. The pitch is reduced as it gets close to the

spinner. The propeller is carved from

birch laid up from (5) ¾” thick planks and glued with resourcenol glue. This gives an overall thickness of 3 and ½

inches. The spinner is a 13” Van’s spinner.

Plans Modifications

A few

minor departures were made from the plans.

The skins

are dimpled and flat head rivets used on all skins. The plans did not call for this refinement.

I used a

landing gear sold by Aircraft Spruce as a CH601XL landing gear, but nothing

like the one in the plans. The gear I

purchased came from an Eastern European company and I understand these are

popular in Zodiacs throughout Europe.

It is made of composite (not aluminum as in the plans) and is not a

single piece like in the plans but 2 separate legs. I beefed up the main gear tunnel and designed and made a set of

inner brackets to adapt this gear.

The plans

called for an electrically actuated flap lever. This plane is using a mechanical one of my own design.

The fuel

tanks were not welded as called for in the plans but are riveted and sealed

with Proseal.

General Information

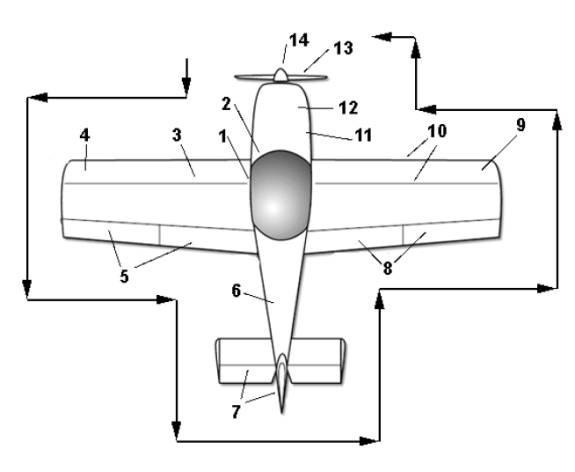

Drawings

Specifications

|

ZODIAC CH601 XLB |

Corvair (100 hp) |

|

|

|

WING SPAN |

27 FT. |

8.23 m. |

|

|

WING AREA |

132 SQ. FT. |

12.3 m.sq. |

|

|

LENGTH

|

20 FT. |

6.1 m. |

|

|

HORIZONTAL

TAIL SPAN |

7 FT. 7 IN. |

2.30 m. |

|

|

RUDDER

TIP HEIGHT |

6 FT. 6 IN. |

1.98 m. |

|

|

EMPTY

WEIGHT |

690 LB. |

312 kg. |

|

|

USEFUL

LOAD |

650 LB. |

294 kg. |

|

|

GROSS WEIGHT |

1,320 LB. |

595 kg. |

|

|

WING

LOADING |

9.85 psf |

48 kg/sq.m. |

|

|

FUEL

CAPACITY (wing tanks) |

= 48 Gal. (US) |

2 x 46 l. |

|

|

POWER

LOADING |

13 LB./HP |

5.9 kg/HP |

|

|

CABIN

WIDTH |

44 INCHES |

112 cm. |

|

|

PROPELLER

(fixed pitch, wood) |

58 INCHES |

285 cm |

|

|

LOAD

FACTOR (G) ultimate * |

+ 6 / - 4 g |

|

|

Performance

|

PERFORMANCE |

Corvair Conversion |

|

|

ZODIAC CH601 XLB |

Gross Weight |

Gross Weight |

|

MAX

CRUISE (sea level, continuous) |

134 mph |

216 km/h |

|

75%

CRUISE @ 8,000 ft. (TAS*) |

155 mph |

250 km/h |

|

VNE |

160 mph |

260 km/h |

|

Vs1 STALL SPEED – no flaps |

51 mph |

82 km/h |

|

Vso STALL

SPEED – flaps down |

44 mph |

70 km/h |

|

RATE OF

CLIMB |

900 fpm |

4.6 m/s |

|

TAKE-OFF

ROLL |

550 feet |

168 m. |

|

LANDING

DISTANCE |

500 feet |

152 m. |

|

RANGE

(std., SM) |

1000 miles |

1056 km. |

|

ENDURANCE

(std.) |

8 hours |

4.9 hours |

Engine

6 Cylinder Horizontally Opposed – Air Cooled

Engine Manufacturer: General Motors

Engine Conversion Daniel Dempsey using William Wynn’s Conversion Guide.

Engine Serial Number: T091RH

Rate Horsepower 100 BHP

RPM Rating 3000 Continuous

Cruise RPM 2700

Compression Ratio 8.0:1

Fuel

Type: 100 LL

Capacity: 50 Gallons, 12.5 Gallons in each of 4 wing tanks

Usable Fuel 48 Gallons

Minimum Fuel Grade 93 Octane (avoid Ethenol)

Oil

Oil sump Capacity: 5 Quarts

Oil Grade- 10W40 Below 32 degrees F.

20W50 Above 32 degrees F.

Castrol Syntec Recommended

Propeller

Type: Fixed Pitch Wood

Manufacturer: Daniel Dempsey

Number of Blades 2

Propeller Diameter 58 inches

Pitch Approximately 56 inches

New Section … Limitations …………………………………………………………….

Operating Weights

Maximum Takeoff Weight 1320 lbs

Maximum Landing Weight 1320 lbs

Maximum Weight in Baggage Area 40 lbs

Limitations

Note: Aerobatic maneuvers are prohibited.

Assumes 1320 Gross Weight, Mid Range CG and Standard Sea Level Conditions

|

SPEED LIMITATIONS |

KCAS (knots) |

KCIS (knots) |

Comments. |

|

VS Stall Speed at max takeoff weight –

Flaps Up |

43 |

|

|

|

VSO

Stall Speed at Max takeoff weight – flaps Down |

38 |

|

|

|

VFE Max Flap Extended Speed |

70 |

|

Do not exceed this speed with

flaps extended. |

|

VA Design Maneuvering Speed |

82 |

|

Do not make full or abrupt control

movements above this speed. |

|

VNE Never Exceed Speed |

140 |

|

Do not exceed this speed in any

operation. |

|

VC Design Cruising Speed |

108 |

|

Do not exceed this speed other

than cautiously in smooth air. |

Cross Wind

Limitation 20 Knots

Service

Ceiling 15,000 feet

Load Factor

Limits

Flap Up: + 4 g to – 2 G

Flap Extended + 2 G to – 0 g

(Ultimate is 1.5 times the limit)

Prohibited

Maneuvers

Intentional spins are prohibited.

Aerobatics are prohibited.

Flight into known forecast icing

conditions is prohibited

Types of

Operation

This airplane is approved for Day

and Night VFR (Visual Flight Rules) when the required equipment is

operational. Non-operational equipment

must be placarded as such.

This airplane is not approved for

operation under Instrument Flight Rules (IFR).

New Section

here **************************************************************

Weight And Balance

General

The size of

the baggage compartment and cabin should not be used as a indicator of the

amount of material that can be carried on the aircraft. These areas are adequate in size to allow

the operator to OVERLOAD the aircraft or cause it to be out of safe

balance. Always calculate the weight

and balance of the aircraft using weights and lever arms of the materials and

people being carried to keep the aircraft within safe load and CG limits.

Overloading

the aircraft will cause lack of climb rate therefore reduce the aircrafts

ability to clear terrain. Overloading

the aircraft also causes undo load to the structure, which can lead to failure

of the structural components and loss of life in flight.

Loading

that causes the aircrafts center of gravity (CG) to become out of the safe zone

can cause the loss of control authority of the control surfaces and or loss of

stability, which can lead to structural failure and loss of life.

Whenever

equipment is added or removed from the aircraft the aircraft should be weighed

again and the weights and center of gravity locations in this manual should be

modified to reflect the actual values.

Installed Equipment List

If equipment is replaced in the aircraft the difference in

weight and the resulting CG must be calculated. Weigh the equipment being removed and the equipment being added.

Multiple the weight times the position to compute the moment. The total weight and the CG must stay in the

acceptable range.

|

Description |

Pounds |

Pos

inches |

Date |

Entered

by |

|

Tachometer |

|

|

|

|

|

Corvair

Engine |

|

|

|

|

|

SU Carburater |

|

|

|

|

|

Mechanical

Fuel Pump |

|

|

|

|

|

Electric

Fuel Pump |

|

|

|

|

|

Alternator |

|

|

|

|

|

Odyssey

PC625 Battery |

13.2 |

|

|

|

|

Air

filter Heat Box |

|

|

|

|

|

Dual

Mufflers |

|

|

|

|

|

Volt

Meter |

|

|

|

|

|

Oil

Pressure Gauge |

|

|

|

|

|

EGT

+ CHT Gauge |

|

|

|

|

|

Oil Temperature Gauge |

|

|

|

|

|

Dimmer |

|

|

|

|

|

Hobbs |

|

|

|

|

|

Clock |

|

|

|

|

|

Air Speed Indicator |

|

|

|

|

|

Vertical Speed Indicator |

|

|

|

|

|

Altimeter |

|

|

|

|

|

Magnetic Compass |

|

|

|

|

|

Differential Pressure Gauge |

|

|

|

|

|

EFIS |

|

|

|

|

|

GPS In Docking Station |

|

|

|

|

|

Communications Radio |

|

|

|

|

|

Transponder |

|

|

|

|

|

Encoder |

|

|

|

|

|

Intercom |

|

|

|

|

|

Five Way Fuel Selector Valve |

|

|

|

|

|

Fuel Gauge |

|

|

|

|

|

Fuel Pressure Gauge |

|

|

|

|

|

Fuel Air Ratio Gauge |

|

|

|

|

|

Battery |

|

|

|

|

|

Engine |

|

|

|

|

|

Electric Fuel Pump |

|

|

|

|

|

Propeller |

10.5 |

|

|

|

|

Spinner |

|

|

|

|

|

Left

Main Fuel Tank |

|

|

|

|

|

Right

Main Fuel Tank |

|

|

|

|

|

Left

Auxiliary Fuel Tank |

|

|

|

|

|

Right

Auxiliary Fuel Tank |

|

|

|

|

|

Aileron

Trim Servo |

|

|

|

|

|

Elevator

Trim Servo |

|

|

|

|

|

Tail

Nav Light |

|

|

|

|

|

Right

Nav Light |

|

|

|

|

|

Left

Nav Light |

|

|

|

|

|

Landing

& Taxi Light |

|

|

|

|

|

Electro

Magnetic Compass |

|

|

|

|

|

ELT |

|

|

|

|

|

Nose

Wheel Pant |

|

|

|

|

|

Right

Main Wheel Pant |

|

|

|

|

|

Left

Main Wheel Pant |

|

|

|

|

|

Sound Proofing |

|

|

|

|

|

ITEM |

WEIGHT

Pounds |

ARM

Inches |

MOMENT

Inch Pounds |

|

Right

Main Wheel |

300 |

-16 |

-4800 |

|

Left Main

Wheel |

300 |

-16 |

-4800 |

|

Nose

Wheel |

150 |

10 |

1500 |

|

Computed

CG EMPTY |

750 |

-10.8 |

-8100 |

|

Calculating

Weight and Balance Prior to Flight |

|

|

|

|

Pilot |

180 |

-28 |

-5040 |

|

Passenger |

170 |

-28 |

-4760 |

|

Baggage |

25 |

-63 |

-1575 |

|

Fuel In L

& R Main Tanks |

144 |

-7 |

-1008 |

|

Fuel in L

& R Aux Tanks |

144 |

-7 |

-1008 |

|

Total

Carried Load |

663 |

|

|

|

Gross |

1413 |

-15.20948337 |

-21491 |

|

Takeoff |

|

|

0 |

|

LIMITS |

1420 |

-18 |

|

|

|

|

-10.8 |

|

|

|

Weight

Within Limits |

CG Within

Limits |

|

The weight

and balance table above shows the measured values in blue. Values that are fixed and do not change are

in black. The calculated values are in

red. The final results are shown with a

yellow background. The values shown are

for example only.

The values in the top part of the chart are based on measured weights and distances at the wheels. These values do not need to be recalculated unless there is a change in the equipment list above. The values on the bottom half of the chart need to be calculated for EACH FLIGHT.

Note: the

weight of fuel can be computed by multiplying 6.07 * Gallons.

(Note: There is a

spreadsheet “Weight&Balance.xls” that will calculate the values for

you. Use of the spreadsheet is the

preferred method as this will eliminate potential human error.)

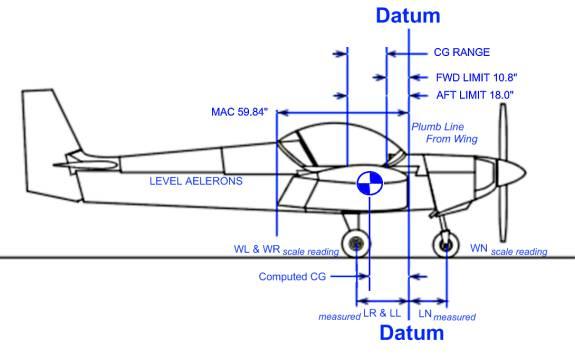

The lever

arm of the item is the distance to the data which is the front leading edge of

the wing.

Distances

forward toward the propeller are positive.

Distances toward the rudder are negative.

To compute

the Moments, multiply the weight of the item times the lever arm of the item.

Compute the

total moment by summing the moments of the items.

Compute the

total weight by summing the weights of the items.

Compute the

CG by dividing the total moment by the total weight.

Note: It would be

mathematically incorrect to sum the lever arms of the items to compute CG.

TBD THE ABOVE ARE FOR

PLANNING ONLY. THE REAL VALUES ARE TBD!

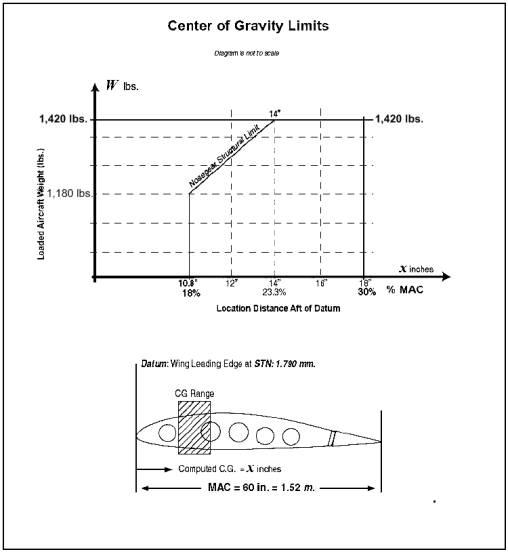

If the

gross weight is above 1,180 pounds plot your CG on the CG Limits chart below to

determine if you are in danger of overloading the nose wheel.

Airplane weighing procedure

A scale

capable of weighing loads of at least 400 pounds is required.

The

airplane should be empty of baggage, fuel and other materials.

Flaps

should up. Canopy and access panels should be closed.

The

airplane should be weighed in doors out of the wind.

The

airplane should be level fore and aft, port and starboard. Use blocks the thickness of the scale to

keep the plane level while it is being weighed. The longeron rail is level reference.

Record

the weight at each of the 3 wheels.

PERFORMANCE

Take Off Distances in Feet

|

Paved |

No Wind |

|

|

|

Altitude

Feet |

29° F |

59° F |

89° F |

|

0' |

450 |

490 |

550 |

|

3000' |

600 |

660 |

740 |

|

6000' |

800 |

880 |

970 |

|

Grass |

|

|

|

|

0' |

540 |

588 |

660 |

|

3000' |

720 |

792 |

888 |

|

6000' |

960 |

1056 |

1164 |

|

|

|

|

|

|

Paved |

10 Knot

Headwind |

|

|

|

Altitude

Feet |

29° F |

59° F |

89° F |

|

0' |

315 |

343 |

385 |

|

3000' |

420 |

462 |

518 |

|

6000' |

560 |

616 |

679 |

|

Grass |

|

|

|

|

0' |

378 |

411.6 |

462 |

|

3000' |

504 |

554.4 |

621.6 |

|

6000' |

672 |

739.2 |

814.8 |

|

|

|

|

|

|

Paved |

20 Knot

Headwind |

|

|

|

Altitude

Feet |

29° F |

59° F |

89° F |

|

0' |

247.5 |

269.5 |

302.5 |

|

3000' |

330 |

363 |

407 |

|

6000' |

440 |

484 |

533.5 |

|

Grass |

|

|

|

|

0' |

297 |

323.4 |

363 |

|

3000' |

396 |

435.6 |

488.4 |

|

6000' |

528 |

580.8 |

640.2 |

Above

distances decrease by approximately 25% for 10 kts of headwind and 40% for 20

kts of headwind.

Landing Roll

|

Paved |

No Wind |

|

|

|

Altitude

Feet |

29° F |

59° F |

89° F |

|

0' |

450 |

490 |

550 |

|

3000' |

510 |

560 |

620 |

|

6000' |

570 |

630 |

700 |

|

Grass |

|

|

|

|

0' |

360 |

392 |

440 |

|

3000' |

408 |

448 |

496 |

|

6000' |

456 |

504 |

560 |

Rate of Climb

(These will be adjusted after flight tests)

|

Altitude

Feet |

29° F |

59° F |

89° F |

|

0' |

744 |

720 |

656 |

|

3000' |

592 |

656 |

720 |

|

6000' |

640 |

720 |

792 |

Cruise Speeds and Range

|

Altitude

(Feet) |

RPM |

CAS - kts |

Range

miles |

|

S.L. 0 |

2500 |

103 |

820 |

|

3000' |

2600 |

108 |

880 |

|

6000' |

2700 |

112 |

900 |

|

9000' |

2800 |

116 |

980 |

These

speeds and ranges are based on a power setting of approximately 75% power. The endurance is about 10 hours depending on

various conditions, such as temperature, altitude and winds aloft and aircraft

loading.

Note:

reducing the power setting can reduce speed and fuel consumption and slightly

increase range.

Best Angle of Climb

TBD

Crosswind

The

demonstrated takeoff and landing crosswind component is 20 kts.

Service Ceiling

15,000

feet

Airspeed Calibration Table in Knots (Flaps Up)

|

KIAS |

35 |

50 |

70 |

90 |

110 |

120 |

|

KCAS |

|

|

|

|

|

|

Airspeed Calibration Table in Knots (Flaps Down)

|

KIAS |

30 |

40 |

50 |

60 |

70 |

80 |

|

KCAS |

|

|

|

|

|

|

The above

calibration shall be measured during the flight testing phase and recorded.

KCAS is

the corrected for instrument error in knots.

KIAS is

the indicated airspeed on the airspeed indicator in knots.

Stall

Speeds at 1400 pounds (Max take off weight)

Flaps up

Vs = _____ KIAS, 46 KCAS.

Flaps

Down Vso = _____ KIAS, 40 KCAS.

Emergency Procedures

The

following paragraphs provide an abbreviated checklist of what to do in different

emergency situations. The next section

will go into each of these in more detail and provide answers to why we follow

these steps.

Engine Fire During Start

Starter

continue cranking

If Engine Starts

Power 1700 momentarily

Engine Shut down and

inspect for damage

If Engine Fails to Start

Ignition OFF

Master Switch OFF

Mixture Full Lean

Fuel OFF

Pull Emergency Battery

OFF

Engine Failure During Takeoff

Throttle IDLE

Brakes APPLY

Flaps UP

Mixture Full Lean

Ignition OFF

Pull Emergency Battery OFF

Engine Failure After Takeoff

Airspeed 60

Mixture FULL LEAN

Fuel Selector OFF

Ignition OFF

Flaps AS REQUIRED

Pull Emergency Battery OFF

Engine Failure In Flight (Restart Procedure)

Airspeed 60

Fuel Selector MOST FULL

Aux Fuel Pump ON

Mixture RICH

Ignition Select OTHER

Carb Heat ON

Check Gauges for cause of power loss

Power Off Landing (assumes off runway)

Airspeed 45->50

Ignition OFF

Pull Emergency Battery OFF

Fuel Selector OFF

Mixture FULL LEAN

Check Seat Belts are secure

Canopy Opening in Flight

Keep your hands on the controls

Lower airspeed to 60

FLY the aircraft

Land as soon as practical

WARNING: Do not try to close the

canopy in flight! Fly the Aircraft.

Precautionary Off Runway Landing

Check that seat belts are secure

Fly as needed to make the field.

Right Before touch down, Emergency Battery OFF

Low Speed, Nose High is best at

touch down.

Brakes WITH CAUTION

Fire In Flight

Look for source of the fire

Electrical Fire (Smoke in cabin):

Master Switch ………….OFF

Vents…………………… OPEN

Cabin Heat ……………. OFF

Fire Extinguisher………. AS NEEDED

Land as soon as

practical.

Engine Fire:

Cabin Heat……………. OFF

Fuel Selector.…………. OFF

Throttle………………… CLOSED

Mixture………………… FULL LEAN

Aux Fuel Pump………. OFF

Proceed with Power Off

Landing

Loss of Oil Pressure

Reduce Power

Prepare for Off Field Landing and

land as soon as practical.

Loss of Fuel Pressure

Aux

Fuel Pump………………… ON

Fuel Selector…………………… Select Most Full

Land at nearest airport and

investigate problem.

High Oil Temperature

Reduce power setting

Land at nearest airport and

investigate problem.

Alternator Failure

Reduce

Electrical Load as much as possible

Cycle Power on Alternator

Land

as soon as possible and investigate

Spin Recovery

Rudder………………………… Full Opposite Direction of Spin

Ailerons……………………….. Full Opposite to Spin Direction

Pitch…………………………… Full Forward

When rotation stops, rudder neutral

and ease controls back to recover from dive.

Engine Roughness

Carb Heat……………………. ON

Mixture……………………….. Adjust for max smoothness

Fuel Selector………………… Switch to most full

Engine Gauges……………… Check

Ignition Select……………….. Change to Other

Prepare for power off landing,

continue to nearest airport.

ICING

Carb Heat……………… ON (adjust for best power)

Turn Back and or change altitude to

obtain outside air less conducive to icing.

Cabin Heat……………. FULL ON

Full Power…………….. Higher Engine

speed reduces icing on propeller.

Plan to land at the nearest airport.

Be prepared for significantly higher

Stall Speed.

Electrical Power System Malfunctions

Volt Meter shows excessive voltage

Alternator………………………………. OFF

Non Essential Electrical

Equipment…. OFF

Land as soon as

practical.

Volt Meter shows low voltage

Radios…………………………………… OFF

Alternator

Fuse…………………………. CHECK

Non Essential Electrical

Equipment…. OFF

Radios…………………………………… ON

Land as soon as

practical

Electric Trim Failure

In the case of electric trim failure the pilot may no longer

be able to neutralize pitch or roll control forces. These may become very heavy.

Adjust speed and power to minimize these forces and be prepared for

extremely high forces required on controls especially during landing.

Lightning Strike

Land as soon as practical to check for damage.

Amplified Emergency Procedures

The

previous section gave emergency procedures in a simple checklist form. In this section we will look at these

emergency situations in more detail..

Engine Fire During Start

Engine Fires during start are often caused by over priming

or flooding the carburetor with gas while attempting to start the engine. In this case the first attempt to extinguish

the fire is get the engine started.

This will consume the excess fuel and help blow the fire out.

If the engine fire doesn’t stop immediately after starting

the engine then the engine should be shut down (Mixture Full Lean) and the fire

put out with the best means available.

Engine Failure During Takeoff

The proper action in an engine out during takeoff depends

largely on the particular circumstances.

If sufficient runway remains to

complete a normal landing, land straight ahead.

Any turn at low speed will increase the risk of a stall

spin, fatal at low altitude. Maintain a

safe airspeed and keep turns at a minimum landing as straight ahead as

possible.

If sufficient altitude has been gained to attempt a restart,

maintain a safe airspeed, check the fuel selector, turn the aux fuel pump ON,

set mixture RICH, and carb heat ON.

If power is not regained proceed with power off landing.

Engine Failure In Flight (Restart Procedure)

First.

Fly the airplane. Set 60 knots for best

glide. Prepare for an emergency

landing.

The most common cause for engine power loss is fuel

starvation. In those cases the engine

power will return soon after fuel supply is restored. This can take about 10 seconds for the empty fuel lines to be

filled once the fuel is flowing.

Turn the auxiliary pump ON, and change the fuel selector

valve to a different tank with fuel in it.

A different tank because sometimes fuel gauges cannot be trusted.

Check the mixture is RICH.

Fuel can be starved by inadvertently leaning the mixture to the fuel

starvation point.

Another common cause of power loss is carburetor ice. Turn the carburetor heat ON.

Change the ignition selector from one coil to another in

case the problem is an ignition problem.

If power is not restored proceed

with an emergency landing.

Power Off Landing

If

a loss of power occurs at altitude, trim the airplane for best glide (about 60

knots) and look for a suitable field.

If altitude is sufficient check the GPS for the nearest airfield. If altitude is sufficient to land safely at

the nearest airport aim for that airfield.

Otherwise pick the best alternative landing sight visible.

If

possible, notify Air Traffic Control of your situation, your location and

intentions.

When

committed to a landing use flaps as needed.

If

landing off field:

The fuel

selector should be OFF and Emergency Battery Cutoff should be pulled to the OFF

position. These steps are to reduce the

risk of fire in an off field landing.

Seat

belts should be tightened.

Land at

the lowest possible speed, keeping in mind the stall speed of 45 knots.

Use

brakes with caution to avoid flipping the airplane on rough or soft terrain.

When the

airplane comes to stop exit the airplane.

Canopy Opening in Flight

The main thing to remember if this

happens is to FLY THE AIRPLANE. A

canopy can come open during flight if not properly latched. There would be a LOT of wind noise in such

an event. Anything lying loose in the

cabin will be sucked out.

If the

canopy should open in flight, lower the airspeed to 60 KCAS, and land as soon

as practical.

If the

flaps are down bring them back up and prepare for a flaps up landing.

DO NOT

TRY TO CLOSE THE CANOPY. The canopy

will be OK if you land the airplane. The force required to close a canopy in

flight is beyond the strength of most people and will only take the pilots mind

off the most important thing, which is to fly the airplane. Especially do NOT remove your seat belts to

reach the canopy. You could be pulled

out of the aircraft.

Fire In Flight

Look for

source of the fire. If the fire is

coming from in the cabin open both fresh air vents to reduce the smoke. Turn the master switch off to remove the

probable electrical source of ignition.

Use a

fire extinguisher to put out the fire.

Land as soon as possible.

If the

fire is in the engine compartment, turn the fuel selector to OFF and close the

throttle. The mixture should be pulled

FULL Lean. Make sure the auxiliary fuel

pump is OFF. Push Cabin Heat OFF to

keep smoke and fire out of the cabin.

Turn the Master switch OFF. Fire

in the engine compartment can be spread as wires loose insulation and begin to

short. Proceed with a power off

landing.

Loss of Oil Pressure

Partial Loss of oil pressure usually

indicates a malfunction in the oil pressure regulating system. Land as soon as possible to prevent engine

damage.

If the pressure gauge indicates a

complete loss of oil pressure it could mean either a low oil level or a faulty

oil pressure sensor or gauge. In either

case proceed to the nearest airport at a reduced power setting and be prepared

for engine failure and a forced landing.

Loss of Fuel Pressure

Loss of fuel pressure can be caused

by a number of failures. This could be

due to fuel exhaustion, failure of the fuel pump or a clogged fuel line. The airplane has a main mechanical pump and

an electric auxiliary pump. Switch the

auxiliary pump on. If fuel pressure

does not return switch to a different fuel tank even if the fuel level gauge

indicates that the tank is full. It is

necessary when switching the fuel selector valve to also switch the tank sensor

selector switch.

Land as

soon a possible to have the fuel system checked to identify the problem. Be prepared to make an emergency power off

landing.

High Oil Temperature

Abnormally high oil temperature may

indicate either a low oil level, or a blockage of the cool air intake

baffles. Land as soon as possible to

resolve the issue. Watch for a loss of

oil pressure. A complete loss of oil

pressure is usually followed by engine failure. Be prepared to make an emergency power off landing.

Alternator Failure

A drop in

voltage can indicate an alternator failure.

If the voltage is 12 volts or less then less current is being provided

than is being consumed. Check for a blown alternator fuse. Reduce the electrical load as much as

possible. Switching the Master switch

off removes all electrical loads other than the ignition system. Switch the alternator off and back on. Land at the nearest airport to investigate

the issue.

Spin Recovery

Intentional

Spins are prohibited. In case of an

unintentional spin apply full opposite rudder to the direction of the

spin. Push the nose down sharply to

gain airspeed. Apply ailerons fully in

the opposite direction of the spin. If

flaps were down, bring them back up.

When rotation stops center the rudder in the neutral position and ease

controls back to recover from dive.

Stalls

Power off

and Power on stalls in this aircraft have similar behaviors. There is no sudden brake, but a gradually

“mushing” as the plane begins to sink.

Recovery is quick when the nose is lowered, usually requiring less than

150 feet of altitude loss.

Engine Roughness

Engine

roughness can be caused by carburetor icing, too lean of fuel air mixture or

running too long with a very rich fuel air mixture. It can also be caused by a failure of an ignition component such

as coil or ignition points. Any of

these cause will usually be accompanied by a loss of engine RPM and power.

In the

case of carb ice, apply carb heat and full power. The engine should soon return to smooth operation.

Check the

fuel air mixture gauge. The optimum

reading is 14:1. If the reading is

higher push the mixture toward rich. If

the reading is lower, pull the mixture toward lean.

If the

cause was a rich fuel mixture it may take some time to recover as this is an

indication of spark plug fowling.

If the

cause was a lean mixture it should return to smooth running quickly when the

mixture is enriched. However running

too lean for any period of time can cause permanent engine damage.

If the

cause is ignition component failure switch the ignition selector from one

ignition to the other. This should

provide immediate resumption of smooth running.

In any

case prepare for a power off landing and return to the nearest airport.

Normal Procedures

Pilots

should become familiar with this section for the safe operation of this

airplane.

Airspeeds for safe operation

|

|

|

KCAS |

KIAS |

|

Vy |

Best Rate

of Climb (flaps up) |

60 |

TBD |

|

Vx |

Best

Angle of Climb (flaps up) |

58 |

TBD |

|

Vc |

Turbulent

Air Operating Speed |

108 |

TBD |

|

|

Landing

Final Speed (flaps down) |

55 |

TBD |

|

Vfe |

Max Flaps

Down |

70 |

TBD |

|

Vne |

Never

Exceed Speed |

140 |

TBD |

|

Vs |

Stall

Speed at Max weight (flaps up) |

43 |

TBD |

|

Vso |

Stall

Speed at Max weight (flaps down) |

38 |

TBD |

|

Va |

Maneuvering

Speed |

82 |

TBD |

|

Vc |

Cruising

Speed |

108 |

TBD |

General Operations

Crosswind

Limitation: 20 Knots

Service

Ceiling: 15,000 feet

Load

Factors Limits

Flaps Up: Positive

+ 4 G, Negative –2 G

Flaps Down: Positive + 2 G, Negative 0 G.

Prohibited

Maneuvers:

Intentional Spins are prohibited.

Aerobatics are prohibited.

Types of

Operation:

This

airplane is approved for the following operations when equipment is in working

order:

Day VFR

Night VFR.

Flight

into known or forecast icing conditions is prohibited.

(Consider

moving weight and balance section to here)

Walk Around

1.

Open

Canopy

2.

Check

Cockpit:

a.

Ignition

key OFF

b.

Master

Switch ON

c.

Throttle

Pull Idle

d.

Fuel

Selector ON

e.

Fuel

Gauges Select Tanks and check quantity

f.

Flaps Down

g.

Master

Switch OFF

3.

Front

Left Wing:

a.

Check

left side of canopy for condition

b.

Drain Fuel

Samples from both left tanks and gascolator checking for containments like

water

c.

Inspect

Left Main Landing Gear and tire for condition.

d.

Look

for leaking brake oil.

e.

Check

Pito

f.

Confirm

Fuel Level visually

g.

Secure

Gas Caps

4.

Left

Wing Tip

a.

Remove

Wing Tie Down

b.

Check

Wing Tip for damage.

c.

Check

Wing Surfaces for damage.

d.

Check

Lights for damage.

5.

Left

Wing Rear:

a.

Check

Aileron condition

b.

Check

Aileron for Freedom of movement.

c.

Check

Left Flap hinge for safety.

d.

Check

Left Flap condition.

e.

Raise

Flaps and check travel.

6.

Fuselage

Left Side:

a.

Check

Left Side of fuselage for damage.

b.

Check

Antennas.

7.

Empennage

a.

Check

Elevator and Rudder condition.

b.

Check

Elevator freedom of movement.

c.

Check

Cables cotter pins and tension.

d.

Check

Elevator hinge safety.

e.

Check Electric Trim Tab Condition

f.

Remove

Tail Tie Down

g.

Check

condition of rudder navigation light.

8.

Right

Fuselage and Rear Right Wing:

a.

Check

access cover secure

b.

Fuselage

condition.

c.

Check

right flap for safety.

d.

Check

right flap condition.

e.

Check

aileron freedom of movement.

9.

Right

Wing Tip:

a.

Check

Right Wing surface for damage.

b.

Check

Wing Tip for damage.

c.

Check

Nav Lights for condtion.

d.

Remove

Right Wing Tie Down.

e.

Check

Angle of Attack Probe.

10. Front Right Wing:

a.

Check

Fuel Level Visually

b.

Sample

Fuel from both tanks for contaminents at the drain.

c.

Check

Right Side of Canopy for Condition.

d.

Inspect

Right Main Landing Gear for condition.

e.

Check

the Tire for air level and general condition.

f.

Look

for leaking brake fluid.

11. Right Side Cowl Rear

a.

Check

Cowling for damage, condition of fasteners.

b.

Check

cabin cool air inlet for blockage.

c.

Open

Dipstick Door and check oil level.

d.

Close

Dipstick Door securely.

e.

Open

Oil Cap Door and check that oil cap is secure.

f.

Check

Noise Gear Bungy.

g.

Check

for buckled mettle around the bungy from hard landings.

h.

Secure

Oil Cap Door completely.

i.

Check

that muffler is not loose.

12. Right Side Cowl Forward

a.

Check

for loose or missing fasteners

b.

Check

for carburetor air blockages.

13. Cowl Front Right Side:

a.

Remove

Tow Bar if present

b.

Check

Nose Gear and Wheel Pant for condition

c.

Check

Tire for Condition and air pressure.

d.

Check

Propeller for condition.

e.

Check

Coil Air Intakes for blockages.

f.

Check

Spinner for condition

14. Cowl Front Left Side:

a.

Check

Air Intake for blockages.

b.

Check

Propeller and Spinner for condition.

c.

Open

Battery Access cover.

d.

Check

that alternator is secure.

e.

Check

that belts are tight and not overly worn.

f.

Look

for buckled mettle from hard landings.

g.

Close

access cover securely.

h.

Look

for loose or missing fasteners.

i.

Check

cabin cool air inlet for blockages.

Inside Airplane Pre-Flight Inspection

1.

Control

Stick should have free smooth operation, no binding or contact with the cabin

seat or instrument panel. There should

be no free play (slack) in the controls, nor should the controls be hard to

move.

2.

Rudder

Pedals should move through the full range of motion smoothly without

binding. Shoes should not catch on

anything around the peddles.

3.

Toe

Brakes should be firm with no tendency to bleed down or lock up. Inspect brake master cylinder area for

leaks. There must be no leaks.

4.

The

instruments should secure and placards in place.

5.

Engine

Controls should be inspected and operate smoothly. Check the friction lock on the throttle for proper

operation. Check the push and release

mechanism on the mixture control for proper operation.

6.

Safety

belts must be in good condition and working order.

7.

Avionics

and electrical checks. Check that the

radios are transmitting and receiving on the desired frequencies. Check the headset and microphone for

operation. Inspect the circuit breakers.

With the master switch on “If it glows, it blows”. Glowing circuit breakers are blown. Test the ELT for operation. Check Lights and GPS. Other instruments can

be checked during the run up.

8.

Check

the canopy latch. Push down hard on the

rail above the latch. You should hear a

‘click’ when the latch is engaged.

9.

The

weight and balance for the aircraft should be carefully done. Determine CG and gross weight are in the

safe range prior to flight.

10. This Pilot Operating Handbook,

weight and balance computation, Operation Limitations, Registration and

Airworthiness Certificate must be on board.

11. All controls and instruments must be

labeled and the Experimental Placard must be readable.

12. The weather must be good enough for

VFR conditions.

13. Windshield should be clean and

clear.

Minimum Equipment

The

following equipment is necessary for DAY VFR flying. If any equipment on this

list is not operational it should be placarded and the airplane should not be

flown.

Remember TOMATO FAMES:

Tachometer

Oil Pressure

Mixture Gauge

Altimeter

Temperature

(CHT)

Oil Temperature

Fuel Gauge

Air Speed Indicator

Magnetic Compass

ELT

Seat Belts

|

|

DAY VFR |

NIGHT VFR |

|

Flight

Instruments |

airspeed

indicator |

magnetic

compass or EFIS |

|

|

altimeter |

|

|

|

compass |

|

|

Engine

Instruments |

Fuel

Level |

Volt

meter |

|

|

Oil

Pressure |

|

|

|

CHT |

|

|

|

Tachometer |

|

|

Lighting |

|

Position

Lights |

|

|

|

Strobe

Lights (anti collision) |

|

|

|

Landing

Light |

|

|

|

Taxi

Light |

|

|

|

Instrument

Lights |

|

|

|

cabin

light (may use flashlight) |

Night VFR

requires these additional pieces of equipment.

Remember FLAPS.

Fuses (spares)

Landing Light

Anti-Collision Lights (on each wing and the rudder)

Position (strobe lights, on each wing)

Source of Electricity (alternator)

To this

we also add

Taxi Light

Panel Lights

Cabin Reading Light (Between the

seat backs, or a flash light)

Placards

Any equipment found not to be operational should be

placarded. The placard should state in

an easy to see warning “<Item Name> Not Functional!” If the item is part of the minimum equipment

for Night Flight a placard should be attached that states “Night Flight

Forbidden”. If any equipment on the day

VFR minimum equipment list is not functional, a placard should be installed

that reads “Flight Forbidden, Aircraft Not Flightworthy” and a placard on the

necessary equipment should be made and piece of tape should be placed over the

ignition switch as a reminder.

Other Considerations

You must

be able to answer the following questions with NO before flying the aircraft.

Has the

aircraft been inspected for structural damage since fly windy or turbulent air

above Va speed?

WARNING: Do not fly the aircraft after flight above Va into

turbulent air without a thorough structural inspection of the wing root area.

Has the

aircraft been tied down outside without control locks?

WARNING: Damage to the controls can

result from being tied down outside on a windy day.

Are there

any notifications or service bulletins from the designer that have not been

complied with?

WARNING: Make sure you are up to

date with service bulletins from the manufacturer.

Are the

control cables loose or overly tight?

WARNING: Do not fly the aircraft

with loose, sloppy or damaged controls.

Is there

a gap between the flap stop while in the up position?

Has the

flap been stepped on?

WARNING: Damage to the flaps can occur if they are stepped

on. A damaged flap can make the

aircraft unsafe to fly.

Are the

colored arcs on the ASI incorrect or missing?

WARNING: No the aircraft limitations

before flying

Does the

canopy not latch securely on both sides?

WARNING: Do not fly the aircraft is

the canopy latch is not functioning properly.

WARNING: Do NOT try to close the

canopy in flight. Fly the aircraft!

Before

Starting the Engine:

Check the controls again. Check brakes and seat belts. Check that canopy is closed securely.

General Operation

Fuel

should be 93 Octane (alcohol free) Auto gas or 100 LL aviation fuel. 100 LL is preferred.

Starting

1.

Fuel

Selector to an appropriate tank.

2.

Fuel

Gauge Selector the selected tank.

3.

Ignition

Selector switch to the right (TBD, this might change)

4.

Mixture,

Rich

5.

Throttle

Full Open

6.

Electric

Fuel Pump ON

7.

Start

by turning ignition switch to the start position and release once started.

8.

Adjust

throttle immediately to idle.

9.

Oil

Pressure Check. (If no pressure in 30 seconds shut down the engine)

If flooding is suspected

1.

Throttle

Full OPEN

2.

Mixture

Full Lean

3.

Start

by turning ignition switch to start position then release when started.

4.

Throttle

back to 1200 RPM.

5.

Mixture

Rich.

6.

Oil

Pressure Check. (If no pressure in 30 seconds shut down the engine)

Taxiing

1.

Check

wind conditions and add extra caution in windy conditions while taxiing.

2.

Set

and check radios and GPS.

3.

Check

Flaps Up.

4.

Set

trim to neutral.

5.

Check

fuel selector on desired tank.

6.

Check

fuel level in all tanks then back to selected tank.

7.

Select

Lights as required, and check.

8.

Check

mixture in Rich 14+ range.

9.

Check

Auxiliary fuel pump On.

Ground Run Up

1.

Warm

up at 900 to 1200 RPM.

2.

Adjust

Mixture to 12:1 ratio.

3.

Minimum

oil temperature is 75 degrees F.

4.

Increase

engine speed to 1700 RPM long enough to perform the following checks.

a.

Switch

ignition selector from right to left. Wait a few seconds then switch it

back. The engine should operate

normally on both ignitions, but the tachometer will operate when the right

ignition is selected.

b.

Pull

carburetor heat on. A slight drop in

engine RPM should be noted.

c.

Return

engine to idle.

5.

Instrument

Check

a.

Oil

Pressure should not be low or fluctuating.

b.

Oil

Temperature should be in the (low – high) range.

c.

CHT

should be in the (low – high) range.

d.

Voltage

should be above 13 volts.

e.

Mixture

should indicate Rich (around 12:1 ratio)

f.

Fuel

Pressure should indicate (3-5psi) guess.. correct later

g.

Altimeter

should indicate field altitude.

6.

Fasten

Seat Belts securely

7.

Check

Canopy is latched securely

8.

Check

freedom of movement of control surfaces.

Normal Takeoff

1.

Release

Brakes

2.

Lineup

with runway.

3.

Slowly

advance throttle to full

4.

Rotate

at approximately Vy, 60 knots.

Climb

1.

Best

angle of climb over obstacles is 58 KCAS (?)KIAS.

2.

Best

rate of climb is 60 KCAS (?) KIAS.

3.

Throttle

Max Power output is 2900 RPM.

4.

Trim

the aircraft to relieve stick pressure.

5.

Check

Oil temperature and pressure is within limits.

6.

Check

CHT remains in limits.

7.

IF oil

temperature or CHT go above limits reduce the rate of climb and increase speed.

Cruise

1.

Aux

pump off.

2.

Throttle

power to 75% (about 2400 RPM) (This should result in 110 to 120 knots)

3.

Trim

for level flight (hands off)

4.

Set

mixture to peek 14:1 ratio.

5.

Maintain

fuel tank balance between left and right tanks. Swap tanks at 15 minute intervals.

6.

When

swapping tanks at the selector valve switch to the corresponding fuel level

sensor.

7.

Check

oil and CHT temperatures at regular intervals.

8.

Check

oil pressure at regular intervals.

9.

Check

electrical system is maintain charge of around 12 volts.

10. If any warning light comes on divert

to the nearest airport.

11. If rough air is encountered reduce

speed to 82 knots.

12. If a speed is seen increasing check

for an unintended decent.

13. If speed is seen decreasing check

for unintended climb.

Decent

1.

Add

carb heat.

2.

During

decent it may be necessary to adjust the mixture to more rich. Look at

maintaining 14:1 ratio.

3.

Adjust

trim for controlled decent.

4.

Decrease

power setting to around 1000 RPM to maintain 60 to 65 knots.

Approach to Landing

1.

Get

radio clearance from tower or warn traffic of approach.

2.

As you

approach for landing add flaps beginning at 75 knots.

3.

Do not

allow air speed to drop below 50 knots.

4.

Push

the stick into the wind to counter cross wind.

5.

Use

rudder to keep the aircraft aligned with the runway.

6.

If

anything is bad (off center, too slow, too fast) then apply full power, and

remove flaps for a go-around.

Landing

1.

Aim

for a touch down speed of 50 to 55 knots.

2.

As you

approach the runway reduce power to idle and bring the nose up slightly to

bleed off extra speed.

3.

Let

the plane settle onto the runway.

4.

At

touch down add backpressure to prevent pitching forward.

5.

At

touch down the nose gear will begin steering. Be prepared for a change in

direction due to opposite rudder.

6.

Apply

breaks carefully.

7.

After landing

flaps up.

Taxiing Back

1.

Remove

carb heat. Carb heat is unfiltered and

it is not recommended for ground operations.

2.

Apply

necessary controls for crosswind controls.

Keep stick into the wind while wind is coming from front. Keep stick with the wind if from back.

Shut Down

3.

Lights

OFF

4.

Mixture

full lean Full Out.

5.

Throttle

to Idle Full Out.

6.

Aux

pump OFF.

7.

Avionics

OFF.

8.

Lights

OFF.

9.

Ignition

OFF.

10. Main Power OFF.

Tie Down

When the

aircraft is not in use it should be anchored to the ground with appropriate tie

downs and the wheels blocked.

Controls

locks should be placed on the controls to prevent wind damage.

If the

aircraft is to be parked for a prolonged period outside the follow precautions

should be taken.

Covers

should be put on pito, AOA probe and covers over engine inlets to prevent birds

or bugs from clogging the cooling fins.

Covers

should also be put over the fuel vents on the bottoms of the wings.

Covers

should be put over the carb inlet to prevent birds from clogging carb inlet.

Covers

should be brightly colored and have flags visible from a casual walk around.

Night VFR Operation

The

aircraft is outfitted for night VFR operation.

Minimum Equipment

Night VFR

requires these additional pieces of equipment.

Landing Light

Taxi Light

Navigation Lights (on each wing and

rudder)

Strobe Lights (on each wing)

Panel Lights

Cabin Reading Light (Between the

seat backs)

After

engine start, panel lights, taxi lights, landing lights, navigation lights and

strobe (anti collision) lights should be turned on.

After

reaching cruise altitude and exiting the airspace around the airport the

landing light and taxi lights can be turned off.